Highland Tank fabricates high quality aboveground steel storage tanks in a wide variety of styles and sizes. These tanks are built in compliance with the U.S. EPA’s regulations for the storage of flammable and combustible liquids and chemicals. Our aboveground tanks are available in a variety of industry-proven cylindrical, rectangular, single-wall, double-wall and fire rated designs in standard and custom sizes from 185 to 57,500 gallons.

Aboveground vertical tanks are manufactured to a variety of standards including; UL-142, API-650 Annex J, API-12F and AWWA for the gas and oil industry, and for water service. Fabricated from carbon or stainless steel, they are available with VOC compliant exterior coatings, specialized interior linings, and many options and accessories. Highland Tank takes pride in the ability to customize our products to meet our customer’s site-specific needs.

The High-LINK® Integrated Systems couples Highland Tank’s superior steel tank products with state-of-the-art electronic management devices and proprietary software to provide real-time data to decision-makers. With our High-LINK® applications you will have the power to optimize the usage and transfer of all your liquid operations. Learn more here.

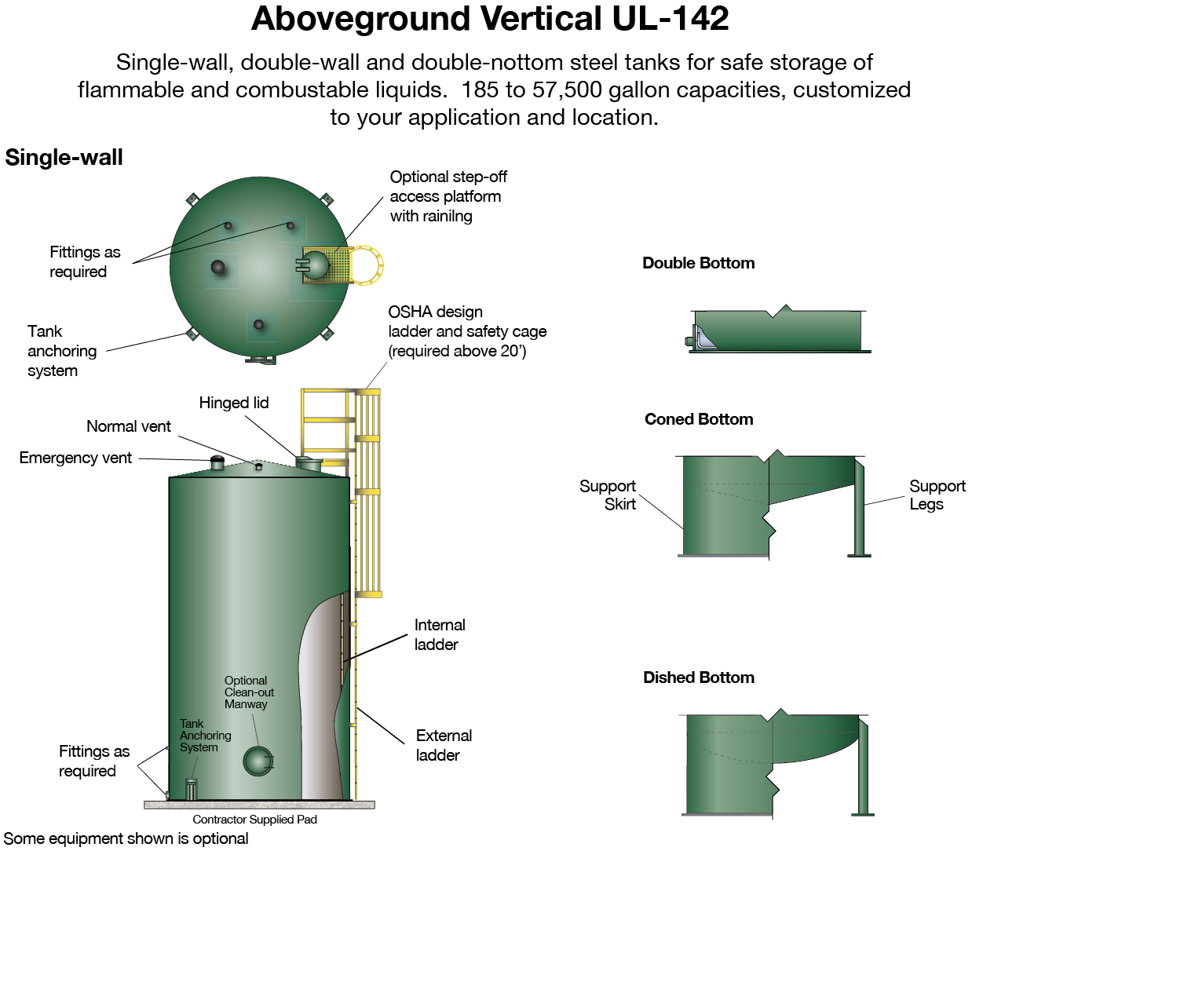

UL-142 aboveground steel storage tanks are engineered and designed to provide a sensible and safe solution to the storage of petroleum products and chemicals at bulk plants, transportation facilities, industrial sites, military and commercial airports.

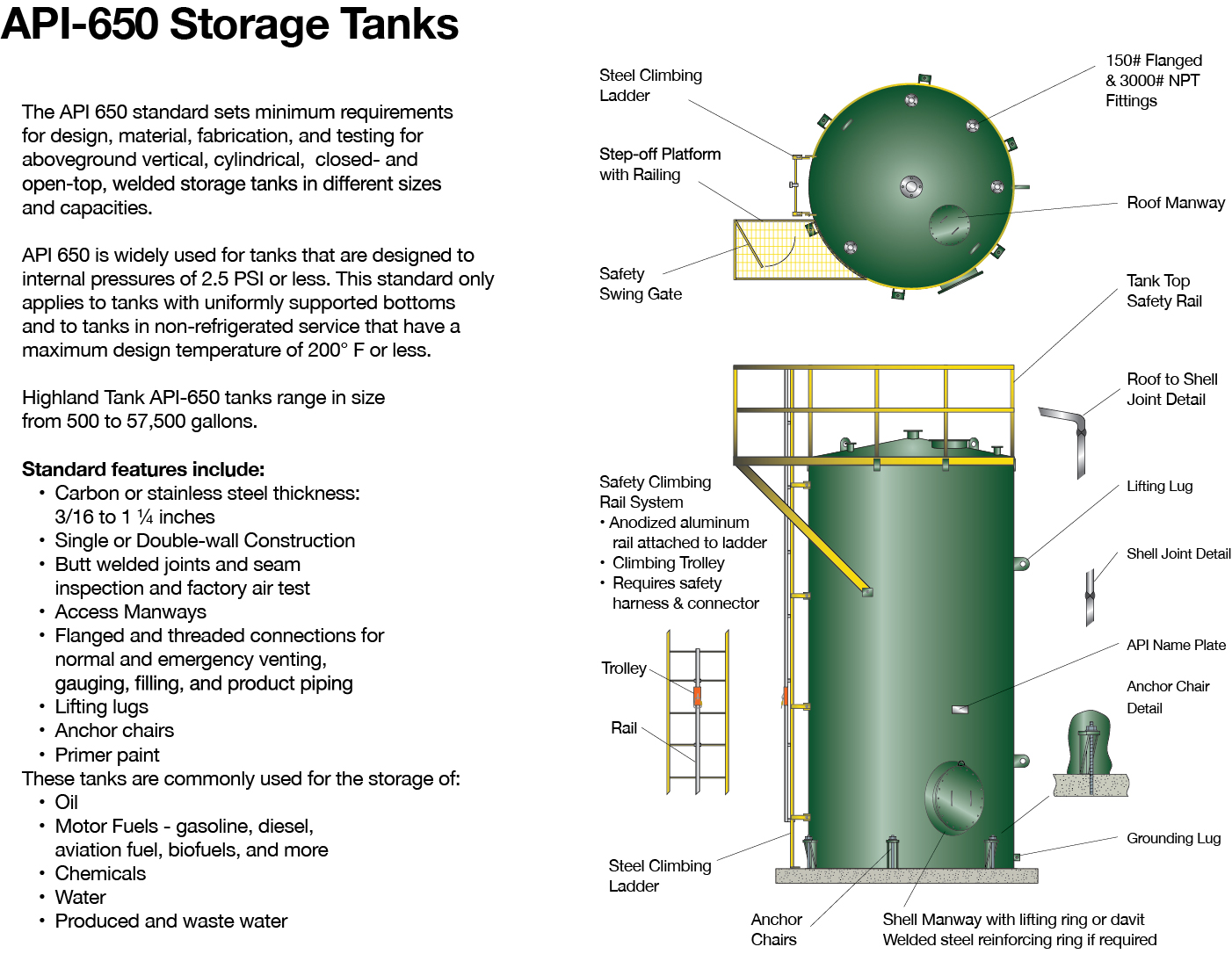

API-650 vertical tanks are commonly used at oil and natural gas midstream facilities located along pipelines, at pumping, compression, or meter stations, and at natural gas processing plants. designs and fabricates aboveground shop fabricated steel storage tanks to API 650, Annex E, F, J and S standards depending on site requirements. This standard allows for the consideration of corrosion allowances, wind loading, and seismicity. The API 650 standard sets minimum requirements for design, material, fabrication, and testing for aboveground vertical, cylindrical, closed- and open-top, welded storage tanks in different sizes and capacities.

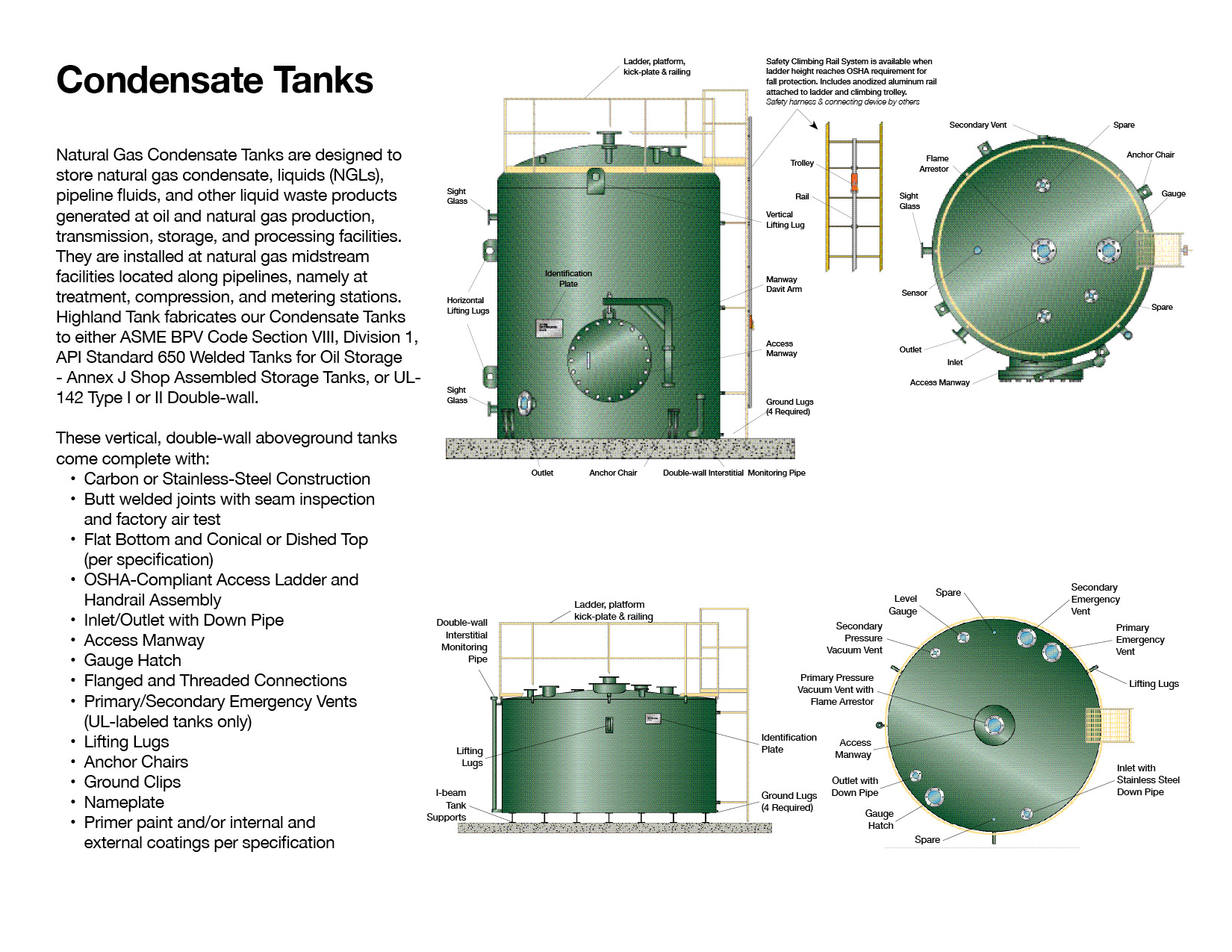

Natural Gas Condensate Tanks are designed to store natural gas condensate, liquids (NGLs), pipeline fluids, and other liquid waste products generated at oil and natural gas production, transmission, storage, and processing facilities. They are installed at natural gas midstream facilities located along pipelines, namely at treatment, compression, and metering stations. They are commonly located after the filter/separators and accumulate various liquids depending on the level of condensation and the changing composition of liquids removed from the gas line. Highland Tank fabricates our Condensate Tanks to either ASME BPV Code Section VIII, Division 1, API Standard 650 Welded Tanks for Oil Storage – Annex J Shop Assembled Storage Tanks, or UL-142 Type I or II Double-wall.

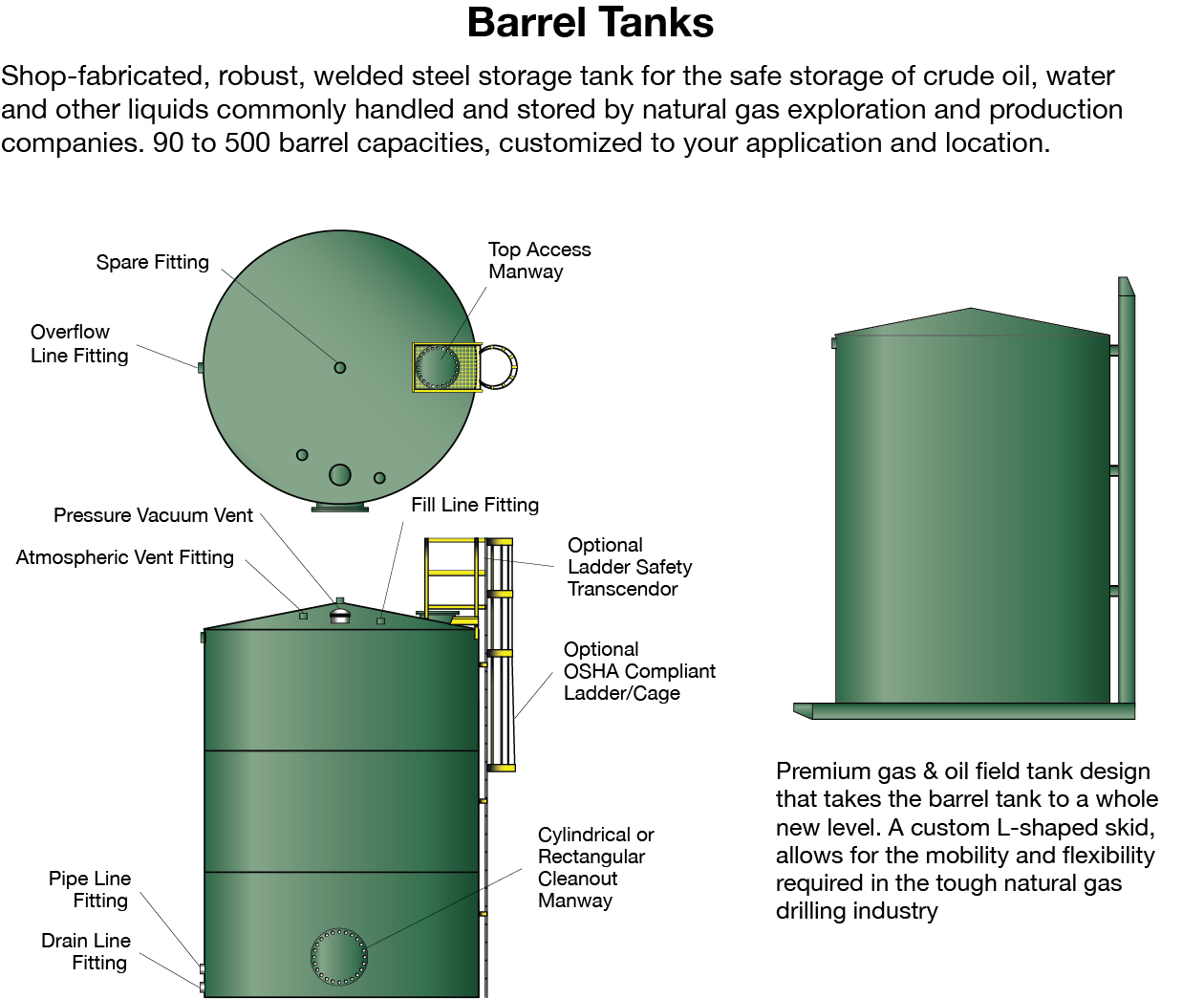

Gas & Oil Field (Barrel) Tanks are designed to provide the natural gas industry with a robust, welded steel storage tank for the safe storage of crude oil, water, and other liquids associated with natural gas exploration and production. These shop-fabricated barrel tanks are the ideal solution for storing a wide variety of liquid products while using the least amount of valuable real estate.

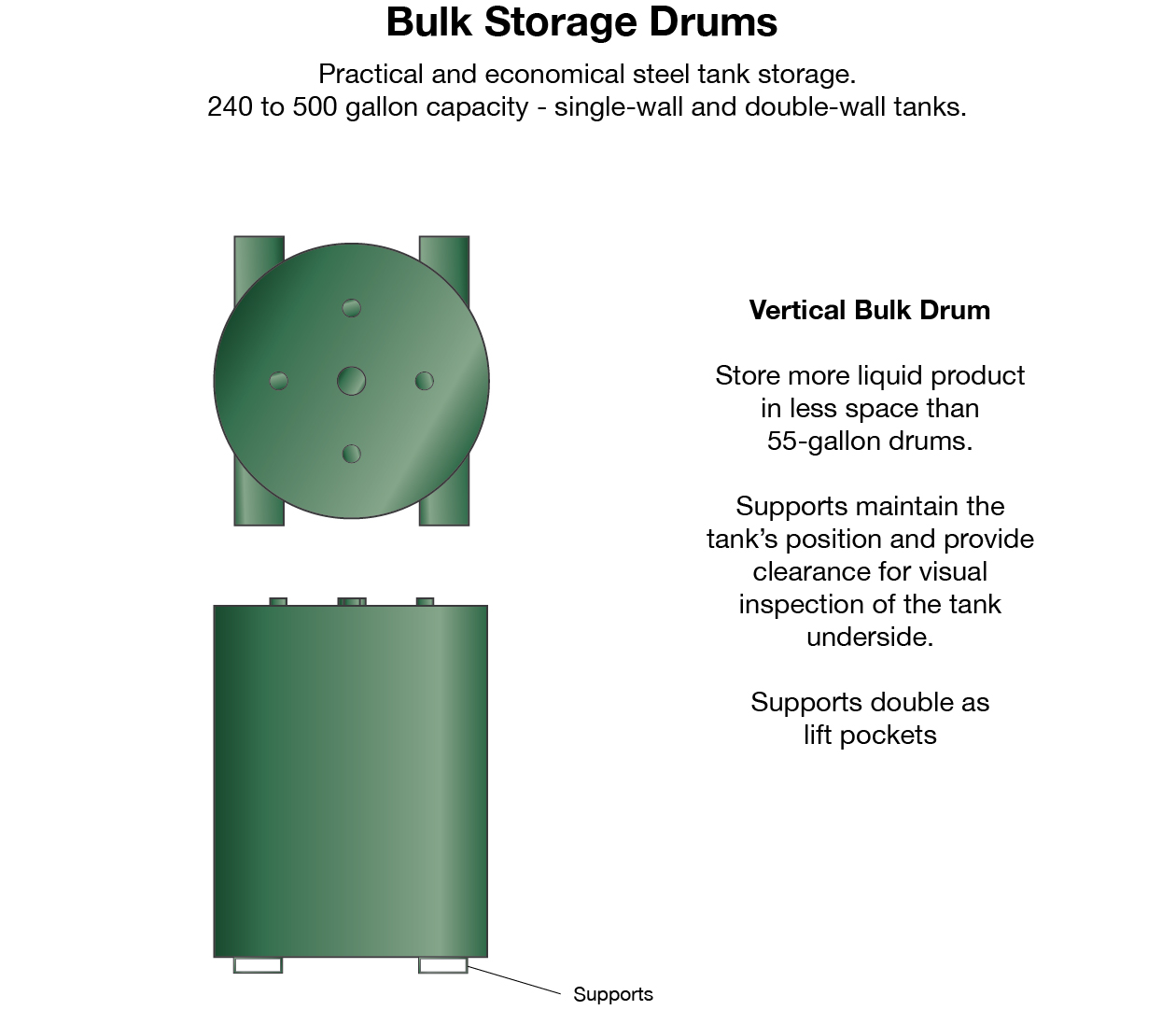

Bulk Drums are practical and economical. They conveniently store more product in less space than 55-gallon drums and allow for bulk purchasing at lower prices. Vertical and horizontal Bulk Drums are available as single-wall and double-wall designs with multiple support options.

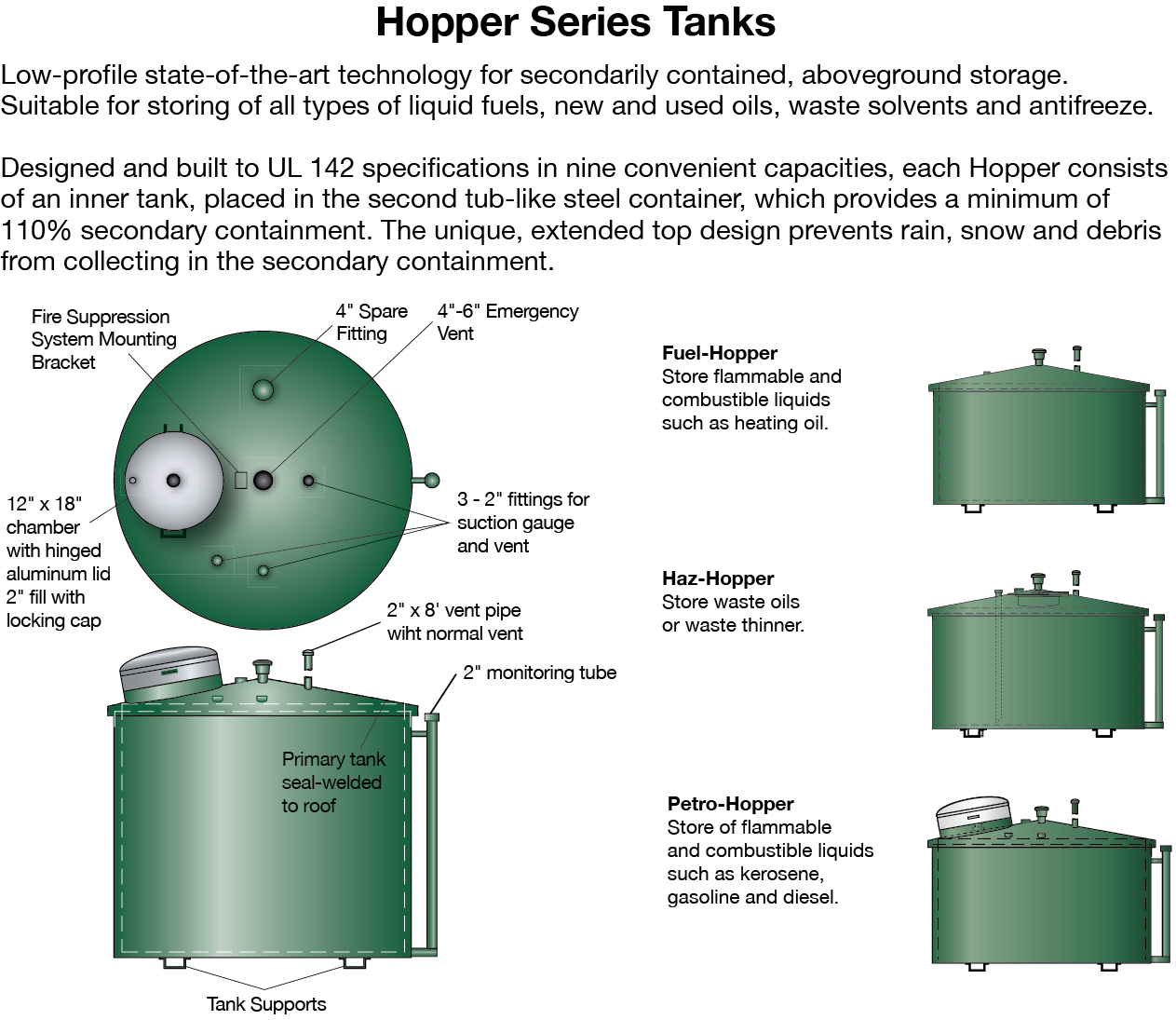

petro-hopper

Highland Tank Hoppers are compact, low-profile, state-of-the-art technology for secondarily contained, aboveground storage. They are suitable for the storage of all types of liquid fuels, new and used oils, waste solvents, and antifreeze. The unique, extended top design prevents rain, snow and debris from collecting in the secondary containment.

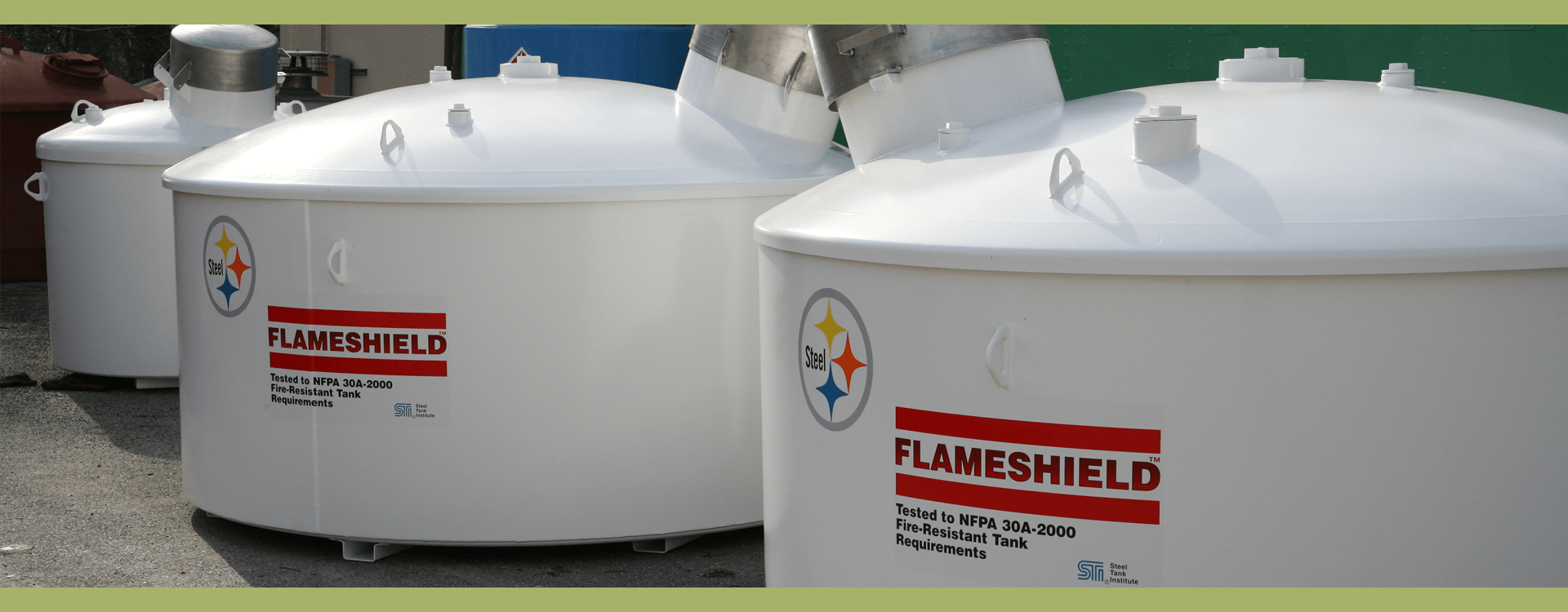

The Flameshield® option is available on all UL-142 double-wall aboveground steel storage tanks manufactured by Highland Tank. Flameshield® labeled tanks are manufactured to strict Steel Tank Institute (STI®) specifications and are subject to the STI’s Quality Assurance program. Each tank carries the Flameshield® and SwRi 97-04 labels. All Flameshield® tanks employ a 360° outer wrap. Flameshield® tanks are available in a wide range of sizes from 240 to 60,000 gallons. Customized compartments and support systems are also available.