Highland Tank has decades of experience in designing and fabricating storage tanks and ASME pressure vessels for the oil and gas industry. We proudly serve the upstream, midstream, and downstream sectors, consistently meeting and exceeding industry standards and customer expectations.

Our team of experienced engineers and fabricators is dedicated to adhering to all codes and standards, including ASME, API, ASTM, AMPP, and other regulatory requirements. We conduct rigorous inspections and testing to ensure every product we deliver meets or exceeds these standards.

Highland Tank, along with our TerraVest Industries sister companies, continues to add value to our extensive range of products. Our comprehensive solutions for the oil and gas industry serve companies involved in the exploration, production, and refining of petroleum hydrocarbons.

Now, as North America’s largest fabricator of natural gas liquid (NGL) storage vessels and transport vehicles, steel storage tanks, and energy processing equipment, we are confident that with our many years of engineering, design, and fabrication experience we will meet and exceed your project requirements.

The High-LINK® Technologies couples Highland Tank’s superior steel tank products with state-of-the-art electronic management devices and proprietary software to provide real-time data to decision-makers. With our High-LINK® applications you will have the power to optimize the usage and transfer of all your liquid operations. Learn more here.

A knockout drum is a vapor/liquid separator used to separate a vapor and liquid mixture. These tanks are widely used at natural gas processing plants, oil refineries, gas pipelines, compressor systems, power plants, and other industrial sites.

A flare knockout drum may be necessary during gas drilling, production, or processing to remove any oil and water from relieved gases. Natural gas found in oil fields often cannot be transported and needs to be burnt. A flare stack protects the pressure vessel and piping from over-pressuring. Flare knockout drums can also be used to gasify heavy fuel oils to produce cleaner energy.

For additional options that may benefit or be required for your specialty asme pressure vessels, please complete our design questionnaire.

Highland Tank Surge Tanks help regulate pressure fluctuations in natural gas pipelines and systems. They absorb sudden changes in gas flow rates, pressure surges, or pressure drops that may occur due to variations in demand, operational changes, or transient events such as valve closures or pump starts/stops. By dampening these pressure fluctuations, surge tanks help maintain stable operating conditions and prevent pressure-related issues such as pipeline ruptures or equipment damange.

For additional options that may benefit or be required for your specialty asme pressure vessels, please complete our design questionnaire.

A slug catcher is a unit that collects large quantities of gas or liquid that exists in the pipeline. These slugs can overload the gas/liquid handling capacity of the plant especially during times where large volumes of liquid that collect in the pipeline are pushed through in a short time. Slug catchers help protect equipment and pipelines downstream from damaging liquids.

For additional options that may benefit or be required for your specialty asme pressure vessels, please complete our design questionnaire.

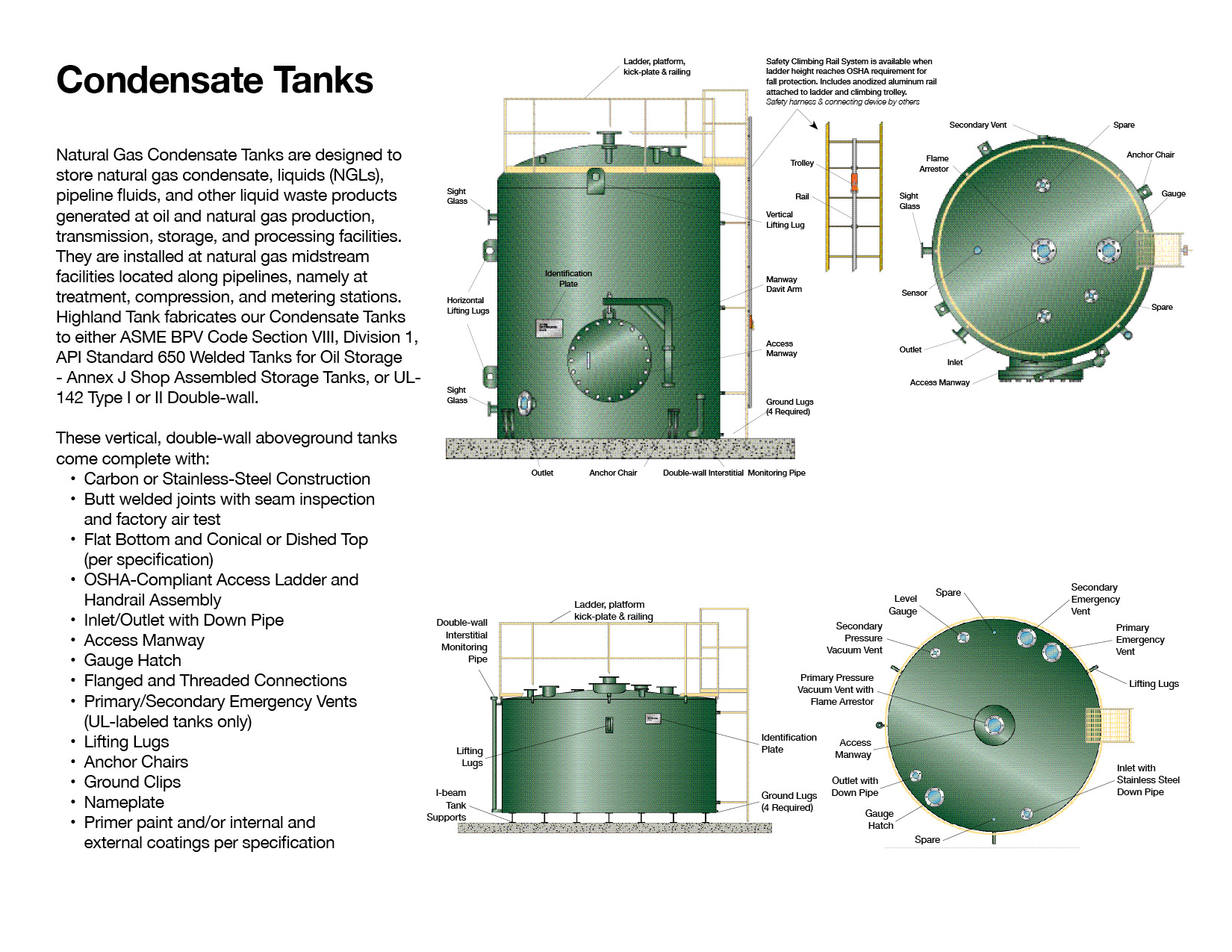

Natural Gas Condensate Tanks are designed to store natural gas condensate, liquids (NGLs), pipeline fluids, and other liquid waste products generated at oil and natural gas production, transmission, storage, and processing facilities. They are installed at natural gas midstream facilities located along pipelines, namely at treatment, compression, and metering stations. They are commonly located after the filter/separators and accumulate various liquids depending on the level of condensation and the changing composition of liquids removed from the gas line. Highland Tank fabricates our Condensate Tanks to either ASME BPV Code Section VIII, Division 1, API Standard 650 Welded Tanks for Oil Storage – Annex J Shop Assembled Storage Tanks, or UL-142 Type I or II Double-wall.